Our high-reliability BGA Reballing service can quickly rework BGA components that require reballing. Reballing is most often required after salvage, rework, or when the alloy of BGA balls needs to be changed from lead-free to leaded. Every BGA component rework project is completed to your exact specifications.

BGA components can also have solder ball problems due to manufacturing defects, improper end-user handling or PCB reclaim processes. Since BGA packages can be expensive, reworking them can deliver significant savings over repurchase.

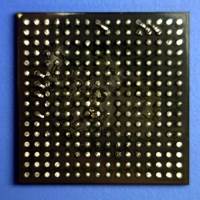

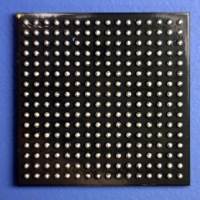

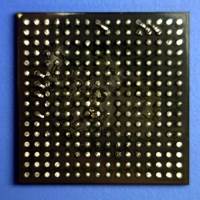

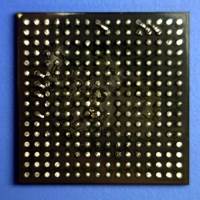

Here is a picture of a BGA before and after the proccess of reballing:

We use reliable, repeatable, and industry-wide proven processes to rework BGA components in compliance with IPC and JEDEC specifications.

Whether you have a small project or need BGA components reworked in volume, we’re ready when you are. All projects are completed in our modern, fully compliant facility.

In addition to BGA component reballing, we have 5 top-line Air-Vac BGA rework systems and a fully trained staff of engineers and operators to support you. This combination provides you with a repeatable process with every project meeting the highest quality standards. We’re recognized as an industry leader in BGA services and have been qualified by companies around the world.

Whether you have one board or one thousand boards for rework, we’re the company to turn to for BGA rework services. BGA rework is a challenge, but not for the experts at Circuit Technology Center.